If you’ve ever admired a car that gleams fresh off the showroom floor, chances are you’re looking at ceramic coating work. Especially here in New Jersey—where harsh weather, road salt, and UV rays can take a toll—ceramic coatings have become a top-tier defense for car owners who want to protect their paint and preserve its beauty.

But beyond the glossy finish and water-beading magic, many drivers ask: What is ceramic coating made of?

In this guide, we’ll peel back the layers—literally—and explore the science, ingredients, and innovation behind ceramic coatings, including their evolution, benefits, and why they’re a wise investment for vehicles across Brick Township, East Brunswick, Edison, and beyond.

A Quick Look Back: The History of Ceramic Coatings

While ceramic coatings might seem like a modern marvel, their roots stretch back decades. Originally developed for aerospace and industrial applications, these coatings were designed to provide heat resistance, durability, and surface protection in extreme environments.

It wasn’t until the early 2000s that automotive manufacturers and detailers began adapting the technology for vehicles. The development of nano ceramic coating was a game-changer. With nano-sized particles, detailers could offer superior paint protection and aesthetic enhancements using a liquid solution that bonds chemically to a car’s surface.

Today, ceramic coatings are a preferred alternative to traditional waxes and sealants—and thanks to brands like Auto Image, drivers in New Jersey can access professional-grade applications tailored to local driving conditions.

What is Ceramic Coating Made Of?

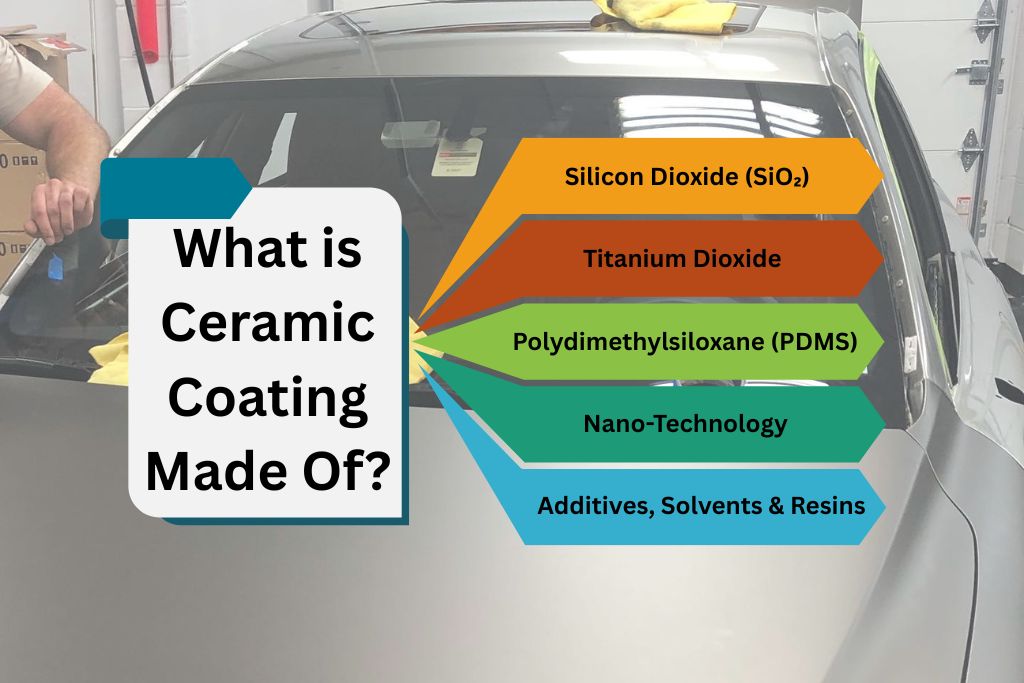

At its core, ceramic coating is a sophisticated blend of ceramic-based compounds, resins, and additives. These ingredients create a thin but incredibly durable layer that adheres to your vehicle’s paintwork. The primary ingredients include:

Silicon Dioxide (SiO₂): The Backbone of Ceramic Coatings

Silicon dioxide, commonly sourced from quartz or sand, is the key ingredient in most ceramic coatings. It creates a hard, glass-like layer on your vehicle’s surface.

Why is silicon dioxide used in ceramic coatings?

When applied, SiO₂ forms a chemical bond with your car’s clear coat, producing a long-lasting protective layer that’s resistant to environmental contaminants, UV damage, and oxidation.

Titanium Dioxide: The UV Shield

Another essential ingredient is titanium dioxide. Often paired with silicon dioxide, this compound significantly enhances the coating’s ability to reflect and block harmful ultraviolet rays.

Why does titanium dioxide enhance UV protection in ceramic coatings?

It acts as a barrier that prevents paint fading, oxidation, and chemical degradation caused by sun exposure—crucial for cars parked outdoors in areas like Spring Lake or Wall Township.

Polydimethylsiloxane (PDMS): The Flexibility Factor

Polydimethylsiloxane, or PDMS, is a type of silicone polymer that adds flexibility and hydrophobic properties to the formula.

Why are resins like PDMS essential in ceramic coating formulations?

While SiO₂ provides hardness, PDMS allows the coating to flex with the surface, preventing cracking while amplifying gloss enhancement and water repellency.

Nano-Technology: The Secret to Invisible Armor

What sets ceramic coatings apart is their use of nano-particles—tiny enough to fill microscopic imperfections in the paint. This creates a uniform, smooth, and ultra-durable finish.

Why is nano-technology important in ceramic coatings?

It enables better adhesion, scratch resistance, and long-term durability—without altering the vehicle’s natural appearance.

Additives, Solvents & Resins: The Performance Boosters

Ceramic coatings also include solvents, stabilizers, and proprietary additives to improve chemical bonding and application.

Why do additives play a role in ceramic coating performance?

They enhance key properties such as chemical resistance, gloss, self-cleaning, and drying time, making the coating more effective and user-friendly.

Why Do Ceramic Coatings Last So Long?

Ceramic coatings outlast traditional waxes and sealants because they chemically bond to your vehicle’s surface instead of sitting on top.

Why is the curing process vital for ceramic coatings?

Proper curing allows the molecules to harden and form a true ceramic layer, increasing lifespan and performance.

For long-lasting results, professional application is essential. Trust Auto Image’s ceramic coating service to ensure your coating is applied and cured correctly for maximum protection.

Protecting Cars in New Jersey with Ceramic Coatings

New Jersey’s roads can be especially harsh—coastal salt air, heavy rain, snow, sun, and road grime all pose threats to your car’s finish. A quality ceramic coating provides year-round protection.

Whether you’re driving through Toms River, Edison, or East Brunswick, ceramic coatings give you peace of mind. When applied by Auto Image, you also benefit from:

- Years of local experience

- Certified technicians

- Premium products from trusted brands like 3M

Benefits at a Glance (Driven by the Ingredients)

Here’s how the unique ceramic coating composition benefits your vehicle:

✅ Hydrophobic effect – Water, mud, and grime slide off easily

✅ Gloss enhancement – Deep, mirror-like shine

✅ UV protection – Shields against sun damage and paint fade

✅ Chemical resistance – Repels bird droppings, bug splatter, and harsh cleaners

✅ Scratch resistance – Protects against light abrasions

✅ Longevity – Can last for years with proper maintenance

Final Thoughts: The Science Behind the Shine

So, what is ceramic coating made of? It’s more than just a glossy finish—it’s an engineered blend of silicon dioxide, titanium dioxide, PDMS, and nano-technology, working together to protect your vehicle from harsh environments while enhancing its appearance.

If you’re in Brick, East Brunswick, or anywhere across New Jersey, and want a trusted expert to apply this high-tech protection, Auto Image has you covered. With decades of experience and two convenient locations, we help car lovers like you achieve long-lasting beauty and performance for your ride.

📍 Serving Drivers In:

Edison | Raritan | South Brunswick | Wall | Spring Lake | Toms River | Brick | East Brunswick

🚗 Ready for a Showroom Shine that Lasts?

Explore our ceramic coating services, or contact us for a free consultation today.

Frequently Asked Questions

Why do ceramic coatings provide hydrophobic properties?

Thanks to PDMS and SiO₂, ceramic coatings repel water, reduce spotting, and make washing easier.

Why do ceramic coatings improve scratch resistance?

Nano-particles create a hard, protective layer that defends against minor scratches from washing and road debris.

Why are solvents used in ceramic coating applications?

Solvents help disperse active ingredients, improve application, and evaporate during the curing process.

Why do ceramic coatings last longer than waxes?

Unlike waxes that wear off quickly, ceramic coatings bond chemically to the surface, offering multi-year protection.